Introduction

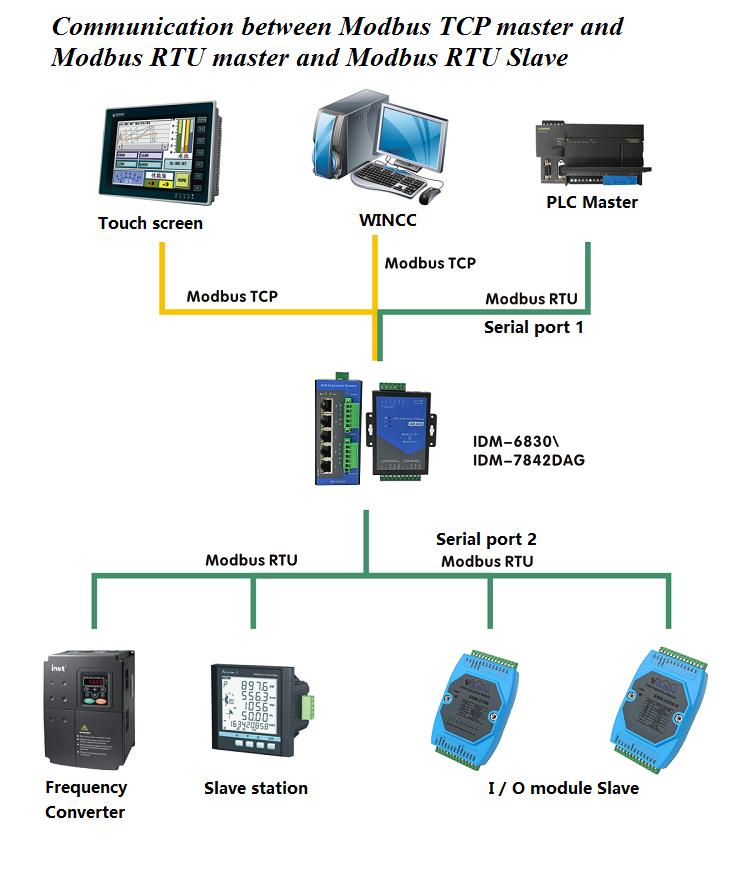

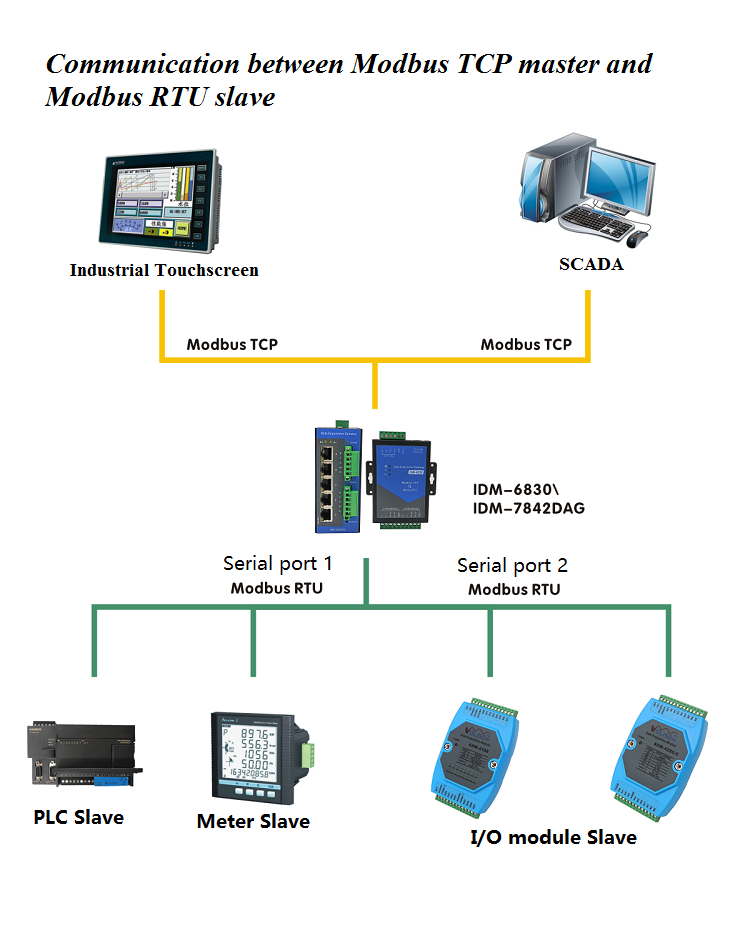

Data acquisition gateway (DAG Gateway) IDM-6832 and IDM-7842DAG are used in the conversion between Modbus RTU protocol data and Modbus TCP protocol data. The serial port supports Modbus RTU master station and slave station function, and Ethernet terminal supports Modbus TCP slave function.

When the serial port is the Modbus RTU master station, it can actively collect the data of the user's Modbus RTU slave station and store it in the internal data buffer. The user's Modbus TCP master station can read or write the data buffer through the Ethernet port, so as to realize the function of data exchange between Modbus TCP master station and Modbus RTU slave station.

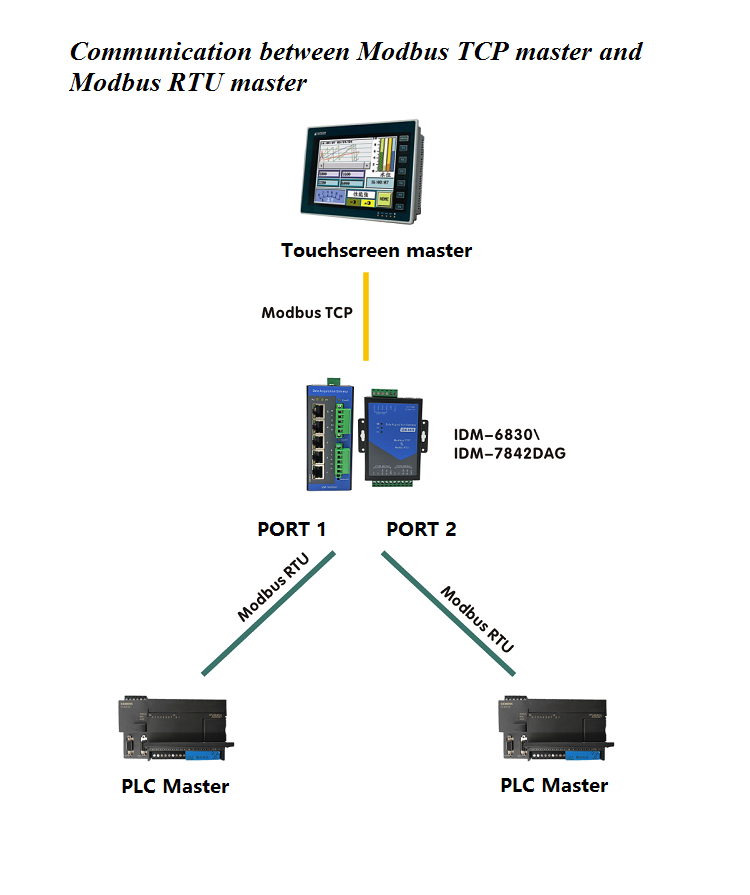

When the serial port is a Modbus RTU slave, the user's Modbus RTU master station can read or write the data buffer through the serial port, and the Modbus TCP master can also read or write the data buffer through the Ethernet port, so as to realize the data exchange function between the Modbus TCP master station and the Modbus RTU master station.

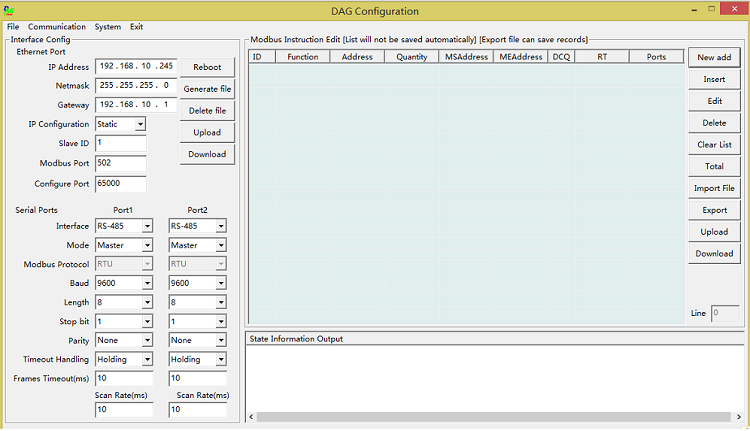

Users can edit serial port settings, Ethernet port settings, operation modes and Modbus RTU instructions through DAG configuration tool, and download them to DAG gateway through Ethernet port. The existing interface settings and Modbus RTU instructions in DAG gateway can also be uploaded to DAG configuration tool through Ethernet port. Users can save these interface settings and Modbus RTU instructions into files for use by other DAG gateway devices.

IDM-6830/IDM-7842DAG supports standard Modbus protocol and can communicate directly with configuration software, PLC, DCS and industrial touch screen.

Functional features

1. Modbus register address mapping, fast response of Modbus TCP request.

2. User defined Modbus RTU instructions, programmable.

3. The scan rate, response timeout and slave response delay can be set.

4. Two serial ports can be used as master station or slave station of Modbus RTU at the same time.

5. Up to five Modbus TCP masters access the DAG gateway.

6. The interface settings and Modbus RTU instructions can be saved to a file, reducing the user configuration time.

7. Equipped with windows configuration tool software, UI friendly, easy to operate.

8. The fault diagnosis function can monitor the communication status of the user's slave station in real time and quickly check the fault.

9. Redundant DC9 ~ 36V dual power input, low power consumption.

10. Industrial grade design, suitable for harsh environment.

Specifications

Product model: IDM-6830

Ethernet port: 1-Port 10/100M self-adaption

Serial port: 2-Ports (RS-485/422)

Power interface: DC9 ~ 36V Dual power

Reverse protection of power: Yes

Power consumption: 100mA@24V(Max)

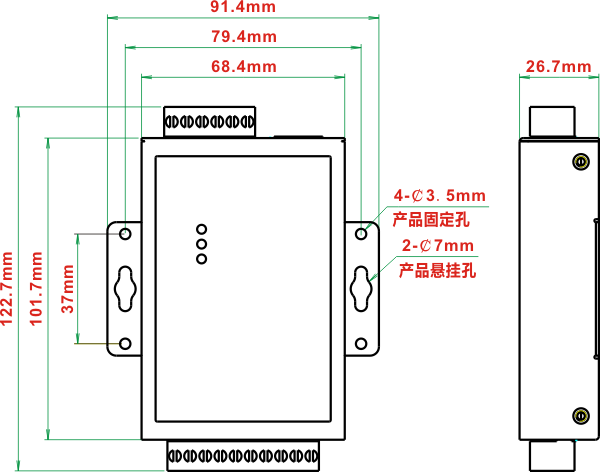

Dimensions: L123 x W92 x H27 mm

Installation Method: Wall built-up

Working temperature: -20~+75℃

Storage temperature: -50~+125℃

Working humidity: 0 ~ 95% (No condensation)

Network protocol: ETHERNET, ARP, IP, TCP, ICMP, Modbus TCP

Number of TCP connections: 5 Maximum

Serial port protocol: Modbus RTU

Number of RTU instructions: 512 Maximum

Serial port baud rate: 300~230400 Bps

Serial port parity: None, Odd, Even

RS-485 drive capability: Maximum 32 slave devices (without repeaters)

Modbus Function code: 0x01,0x02,0x03,0x04,0x05,0x06,0x0F,0x10

Modbus Data buffer

0X (Coil output) 8192, Address (0-8191 = 0x0000-0x1FFF)

1X (Discrete input) 8192, Address (0-8191 = 0x0000-0x1FFF)

3X (Input register) 4096, Address (0-4095 = 0x0000-0x0FFF)

4X (Hold register) 4096, Address (0-4095 = 0x0000-0x0FFF)

Fault diagnosis buffer

1X (Fault flag area) 512, Address (8192-8703= 0x2000-0x21FF)

3X (fault code area) 512, Address (4096-4607= 0x1000-0x11FF)

Operation mode

Each serialportofDAGgateway has Master and Slave two operation mode:

In Master mode, RS-485 port can connect up to 31 Modbus RTU slave devices without repeater, this mode is used for communication between Modbus TCP master station and Modbus RTU slave station.

In Slave mode, this serial port can be connected to a Modbus RTU master. At this time, Modbus TCP master station can communicate with Modbus RTU master station, Modbus TCP master station and Modbus RTU master station can also communicate with Modbus RTU slave station at the same time, and two Modbus RTU master stations can communicate with each other.

Modbus RTU instruction

The DAG gateway supports up to 512 Modbus RTU instructions. Users can edit Modbus RTU instructions using DAG Configuration software according to the functions of Modbus RTU slave devices. After the instruction is downloaded to DAG gateway, DAG gateway will send each instruction to Modbus RTU slave station periodically. The instruction includes 8 items: Slave ID, Function Code, Start Address, Register Quantity, Mapping Start Address, Response timeout, DC- quickly, Ports.

DAGConfiguration tool software

Dimensions

Contact: Ms Liao(Sales) / Email: liao.yanping@st-inno.com

Phone: 155-5805-0803

Tel: 400-1011-310

Email: liuchangshandx@126.com (Technical support)

Add: room 401, building D, No. 16, Xiang Mao Road, Hangzhou, Zhejiang, Gongshu District